Success Story

Das Sozialforschungsinstitut DemoSCOPE bietet Kunden eine neue digitale Lösung im Bereich Survey Research und Data Science und bricht mit Konventionen in diesem Business.

mehrSuccess Story

Der HR Hub ist ein modernes Selfservice-Portal für Mitarbeitende mit übersichtlichen User Journeys und umfangreichen People Analytics.

mehrSuccess Story

Die vernetzten Kaffeemaschinen von Thermoplan nutzen eine innovative Cloud-Lösung von bbv und beliefert Kunden wie Starbucks oder Nespresso.

mehrSuccess Story

Swisscom Health setzt auf moderne Lösungen aus der Cloud, die zeit- und ortsunabhängiges Arbeiten ermöglichen. bbv plante und realisierte die Migration der curaBILL-Applikationslandschaft.

mehrFactsheet

bbv Software Services bietet mit den internationalen Shoring-Teams in Vietnam und Griechenland eine sichere, globale Alternative für die Softwareentwicklung.

mehrSuccess Story

ALSO Dolly+ ermöglicht eine smarte Lagerung und Logistik wertvoller Ware, transparentes Tracking und die Optimierung von Betriebsprozessen.

mehrSuccess Story

bbv hat das Produktionssystem curabill der Swisscom Health AG um ein webbasiertes Erfassungs- und Informationssystem für das Forderungsmanagement im Gesundheitswesen erweitert. Besonderer Entwicklungsschwerpunkte lagen auf der «Usability» der Benutzeroberfläche und der Sicherheit der Finanz- und Patientendaten.

mehrSuccess Story

Der Pilatus ist ein beliebtes Ausflugziel. Für das perfekte Bergerlebnis hat bbv für die PILATUS-BAHNEN ein neues Reservationssystem entwickelt.

mehrPoster

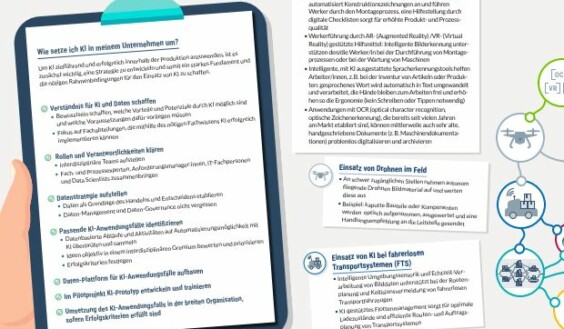

Das Poster bietet eine klare Übersicht, die hilft KI zielführend und erfolgreich innerhalb der Produktion anzuwenden.

mehrBooklet

Ziel dieses Booklets ist es, zu Beginn eines Projekts oder einer Produktentwicklung Hilfestellungen anzubieten. Der Fokus liegt vor allem auf den Themen, die bei der Auswahl der Plattform oder generell zu Beginn des IoT-Vorhabens häufig vernachlässigt werden. Dazu bietet es zahlreiche Checklisten.

mehr